A whole new design for a new printer...

After I got some experience in 3D printing I found that a 3D printer must have more specifications to be able to give reliable and accurate prints and the first thing I can think about to get more accuracy is rigidity, and actually this is one of the most important things that delta printers needs , so that gave me the decision to change the whole design and use one of my favorite kinematics that I always wanted to try not only to get more rigidity but also to get more printing speed so I chose to start with the core xy kinematic.

with corexy I can make the X and Y axis as one gantry and fix it to the printer frame that have a separate Z axis

I chose to make the frame out of 5x5cm with 3mm thick angle aluminum bar and of course I used the delta printer to print all plastic parts I designed

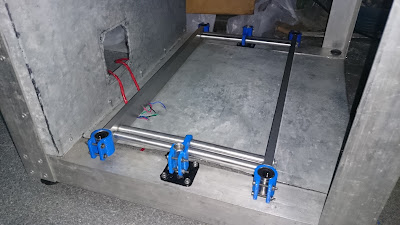

and here are some pics for the frame and the XY gantry with the printer bed frame I made

with corexy I can make the X and Y axis as one gantry and fix it to the printer frame that have a separate Z axis

I chose to make the frame out of 5x5cm with 3mm thick angle aluminum bar and of course I used the delta printer to print all plastic parts I designed

and here are some pics for the frame and the XY gantry with the printer bed frame I made

Comments

Post a Comment